Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

Mjesto podrijetla:

Zhejiang, Kina

Naziv marke:

ZK

Polje primjene:

EV, automobil, električni bicikl, stropni ventilator, kućanski uređaji, AI pametni humanoidni roboti, itd.

Tip:

Mikro motor

Izgradnja:

Trajni magnet

Komutacija:

Bez četkica

Značajke motora:

Visoki zakretni moment Velika gustoća snage

PM oblik:

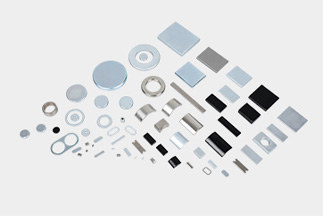

Pravokutni/blok, prsten, luk/segment ili prilagođeno

+86-15857968349

+86-15857968349

Magneti igraju ključnu ulogu u motorima istosmjerne struje bez četkica (BLDC), koji se obično koriste u raznim primjenama, uključujući električna vozila, vjetroturbine i robotiku. U BLDC motoru, magneti stvaraju magnetsko polje potrebno za rad motora. Postoje dvije vrste magneta koji se obično koriste u BLDC motorima: neodimijski željezo-bor (NdFeB) magneti i feritni magneti. Ovi se magneti razlikuju po sastavu, magnetskim svojstvima i oblicima, što utječe na njihovu izvedbu i prikladnost za različite primjene.

Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

With a strong engineer team and professional production lines, Zhongke can design and produce magnet in all shapes according to your needs.

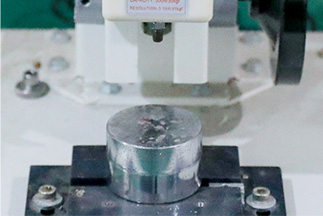

If you are not sure about the performance parameters of the product, you can send us a sample, we will do a professional test, determine the performance parameters and issue a report for your reference.

Exclusive customer service 7x24 hours to get professional help, make an appointment with a professional technical engineer to get a comprehensive solution.

Publicly traded listed magnet company in China. Our magnet supplied to many large, medium-scale customers including SAMSUNG, Nidec, Xiaomi, GREE, Midea, WOLONG, amazon, etc. We manufacture type of Ferrite Magnet and Neodymium(NdFeB) Magnet for electric motor, widely used in the field of new generation consumer electronics and energy-saving home appliances.

Just tell us your applied industry, product performance parameters, quantity and size, we will recommend the most suitable magnet for you.

NdFeB magneti izrađeni su od neodimija, željeza i bora, a poznati su po svojoj visokoj magnetskoj snazi, maloj težini i kompaktnoj veličini. Ovi se magneti obično koriste u motorima i generatorima visokih performansi zbog svojih izvrsnih magnetskih svojstava, kao što su visoka koercitivnost, visoka gustoća energije i visoka Curiejeva temperatura. NdFeB magneti dolaze u različitim oblicima i veličinama, ovisno o zahtjevima njihove primjene.

Najčešći oblici su:

1. Pravokutni/blok NdFeB magneti: Ovi magneti su pravokutnog oblika i koriste se u motorima s pravokutnim dizajnom rotora. Omogućuju snažno magnetsko polje i veliku brzinu vrtnje, što ih čini prikladnima za motore velike brzine.

2. Prstenasti magneti NdFeB: Ovi magneti su okrugli ili prstenasti i koriste se u motorima s kružnim dizajnom rotora. Oblik prstena omogućuje jednoličnije magnetsko polje, što rezultira glatkijim radom i manje buke.

3. NdFeB magneti u obliku luka ili segmenta: Ovi magneti su dizajnirani da stanu u kružni luk ili segment i koriste se u motorima sa zakrivljenim rotorima. Pružaju snažno magnetsko polje i veliki zakretni moment, što ih čini prikladnima za primjene s visokim zakretnim momentom.

Feritni magneti, također poznati kao keramički magneti, izrađeni su od željeznog oksida i drugih metalnih oksida i poznati su po svojoj visokoj koercitivnosti i niskoj cijeni. Feritni magneti se obično koriste u motorima niskih performansi, kao što su kućanski aparati i pumpe za vodu.

Feritni magneti dolaze u različitim oblicima, uključujući:

1. Pravokutni/blok feritni magneti: Ovi magneti su pravokutnog oblika i koriste se u motorima s pravokutnim dizajnom rotora. Oni pružaju slabije magnetsko polje od NdFeB magneta, što rezultira nižim momentom i brzinom vrtnje.

2. Feritni magneti u obliku prstena: Ovi magneti su okrugli ili prstenasti i koriste se u motorima s kružnim dizajnom rotora. Oni pružaju slabije magnetsko polje od NdFeB magneta, što rezultira nižim momentom i brzinom vrtnje.

3. Feritni magneti u obliku luka ili segmenta: Ovi magneti su dizajnirani da stanu u kružni luk ili segment i koriste se u motorima sa zakrivljenim rotorima. Oni pružaju slabije magnetsko polje od NdFeB magneta, što rezultira nižim momentom i brzinom vrtnje.

Izbor oblika magneta ovisi o zahtjevima dizajna motora, radnim uvjetima i ciljevima izvedbe.

: 1. Pravokutni/blok magneti: ovi magneti imaju visoku gustoću magnetskog toka i prikladni su za primjene pri velikim brzinama. Međutim, zbog svoje ograničene geometrije, oni možda neće pružiti jednolično magnetsko polje, što će rezultirati začepljenjem ili valovitošću momenta.

2. Magneti u obliku prstena: ovi magneti daju ujednačenije magnetsko polje i prikladni su za aplikacije s malim brzinama i niskim momentom. Međutim, oni možda neće pružiti dovoljnu magnetsku snagu za aplikacije velike brzine.

3. Magneti u obliku luka ili segmenta: ovi magneti daju veliki zakretni moment i prikladni su za primjene s visokim zakretnim momentom. Međutim, njihova geometrija može uzrokovati neravnomjernu distribuciju magnetskog polja i začepljenja.

4. Feritni magneti: feritni magneti su jeftiniji od NdFeB magneta i mogu izdržati više temperature. Međutim, oni imaju manju magnetsku snagu i prikladni su samo za aplikacije s niskim učinkom.

Zhejiang Zhongke Magnetic Industry Co., Ltd. je vodeći proizvođač NdFeB i feritnih magneta u Kini. Tvrtka ima preko 20 godina iskustva u magnetskoj industriji i zapošljava preko 1000 ljudi. Prednosti Zhejiang Zhongke Magnetic Industry u proizvodnji različitih oblika magneta su: 1. Napredna tehnologija: Zhejiang Zhongke Magnetic Industry Co.,Ltd. koristi naprednu proizvodnu tehnologiju i opremu, kao što je metoda lijevanja trake, dekrepitacija vodikom i mljevenje u mlaznom mlinu, za proizvodnju visokokvalitetnih NdFeB i feritnih magneta različitih oblika. 2. Prilagodba: Zhejiang Zhongke Magnetic Industry Co., Ltd. nudi prilagođene dizajne i veličine magneta kako bi zadovoljio specifične potrebe kupaca. Tvrtka ima snažan tim za istraživanje i razvoj koji može dizajnirati i proizvesti magnete s preciznim tolerancijama i složenim geometrijama. 3. Kontrola kvalitete: Zhejiang Zhongke Magnetic Industry Co., Ltd. ima rigorozan sustav kontrole kvalitete koji osigurava da magneti zadovoljavaju međunarodne standarde, kao što su ISO9001:2015, ISO14001:2015 i OHSAS18001:2007. Tvrtka provodi stroge postupke ispitivanja i inspekcije, uključujući ispitivanje magnetskih svojstava, mjerenje dimenzija i vizualni pregled. 4. Konkurentne cijene: Zhejiang Zhongke Magnetic Industry Co., Ltd. nudi konkurentne cijene za svoje NdFeB i feritne magnete, što ih čini privlačnom opcijom za kupce koji traže visokokvalitetne magnete po razumnoj cijeni.

Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances.

The company's current production process of permanent ferrite magnets is as follows: the purchased pre-fired materials are mixed according to their own formula and ingredients, and after being ball milled by a ball mill, ferrite is produced through steps such as precipitation, wet pressing, sintering, and grinding. Body magnetic tiles, ferrite magnets and other finished products. The specific production process flow chart is as follows:

The strontium ferrite calcined material (the main component is SrFe12O19) is mixed with calcium carbonate, silicon dioxide, strontium carbonate, lanthanum oxide, cobalt oxide and other ingredients according to the formula ratio.

The raw materials are added with water and pulverized by a ball mill to form a slurry, which is placed in a sedimentation tower for precipitation.

The dehydrated material formed by precipitation is made into a green body through an automatic press in a normal air environment.

The raw body is sintered at high temperature into a mature body through a wet-pressed magnetic tile electric-fired roller kiln or a wet-pressed magnetic steel gas-fired roller kiln.

The cooked blank is processed by a fully automatic grinding machine processing line to form a finished product.

The magnetic properties, appearance, size and other indicators of the magnets are inspected, packed and put into storage.

The company has applied and improved a number of advanced technologies in the industry, such as high-performance ferrite slurry stabilization technology and secondary ball milling batching technology, which has solved the quantitative problem of material added in the preparation process. And we use double coupling dispersion and fine grinding to overcome the problems of slurry agglomeration and particle size distribution consistency. The performance of the slurry obtained in the ball milling process is more stable, which reduces the unit operating time of the ball milling equipment, improves product quality, and reduces production costs.

The company uses a unique new green release agent independently developed to prepare magnetic tiles. The new green release agent is an organic combination of microbial technology and surface release treatment technology, which can degrade oil molecules, reduce the oil content of the release agent, and restore the surface. active lipophilic factor. The product is combined with the surface release process, and the release effect of the magnetic tile is improved through a new release agent, and the surface finish of the blank is improved. The demoulding technology has the characteristics of simple preparation method and convenient application, and improves production efficiency.

By transforming the sintering preheating system equipment, the company reduces the water content of the sintered green body in the kiln, greatly reduces the waste rate caused by factors such as cracking and lack of oxygen during sintering, and improves the sintering density and mechanical strength of the product. Obtain good microstructure and magnet properties. The company has also realized the sintering base temperature that products with different performances can adapt to through formula adjustment. Products with different specifications, sizes and performances can be co-fired at the same temperature, which significantly improves the production efficiency of the sintering process. In addition, in terms of veneer loading and billet loading, the company has adopted a bulk stacking method that conforms to the company's product features of small shape and light weight after many tests, realizing heavy veneer loading, good sintering atmosphere, and high sintering yield. good effect.

By optimizing the parameters of grinding machines and other processing equipment and improving the process technology, the company has improved the consistency of product thickness to ≤0.02MM within L30MM and ≤0.04MM within L50MM, and has mastered the technology of three-phase motor magnets produced by grinding tooling. Breakthroughs have been made in technical difficulties in the industry, such as product precision and stable equipment performance, and certain innovations have been achieved in technology and equipment.

The company's magnetic tile products are developing in the direction of high efficiency, low consumables, and low energy consumption. For example, through atomic substitution and compound doping, the rare earth-free ZK-5B high-performance motor magnetic tile independently developed by the company reduces the coagulation of magnetic powder, improves the orientation effect, improves the material performance and reduces the production cost by using strong magnetic field to suppress and adding a double dispersant.