Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

Naziv marke:

ZK

Tip:

Sinterirano Trajno

Složeno:

Magnet rijetke zemlje

Oblik:

Blok, luk/segment

Primjena:

generator vjetroturbina

Dimenzija/veličina:

Prilagođeno

Naziv marke:

ZK

Razred:

N35-N52(H,SH,UH) ili prilagođeno

Premazivanje:

Zn, Ni, crni epoksid, Ni-Cu-crni epoksid ili prilagođeni

Radna temperatura

80-250 stupnjeva

Smjer magnetizacije

Aksijalni, promjerni ili prilagođeni

Mjesto podrijetla:

Zhejiang, Kina

Vrijeme isporuke:

15-20 dana

Luka:

NingBo, CN

Sposobnost opskrbe

3000 tona godišnje

+86-15857968349

+86-15857968349

NdFeB magneti se koriste u generatorima energije vjetra zbog svoje velike magnetske snage, izvrsnih performansi i isplativosti. Obično se koriste u generatorima vjetroturbina s izravnim i poluizravnim pogonom, gdje daju visok moment i pouzdanost pri malim brzinama. NdFeB magneti imaju prednost u odnosu na druge magnetske materijale zbog svoje visoke koercitivnosti, visoke remanencije i izvrsne temperaturne stabilnosti. Obično se proizvode tehnikama metalurgije praha i mogu se oblikovati u različite oblike i veličine, uključujući diskove, blokove, prstenove i lukove/segmente. Ocjene performansi NdFeB magneta kreću se od N35 do N52 ili s H, SH, UH, s višim ocjenama koje pružaju veću magnetsku snagu i bolju izvedbu u ekstremnim uvjetima.

Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

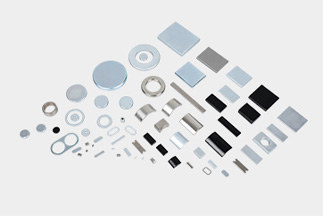

With a strong engineer team and professional production lines, Zhongke can design and produce magnet in all shapes according to your needs.

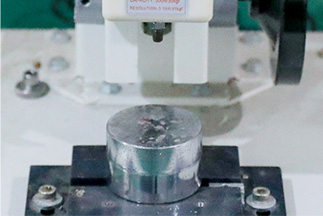

If you are not sure about the performance parameters of the product, you can send us a sample, we will do a professional test, determine the performance parameters and issue a report for your reference.

Exclusive customer service 7x24 hours to get professional help, make an appointment with a professional technical engineer to get a comprehensive solution.

Publicly traded listed magnet company in China. Our magnet supplied to many large, medium-scale customers including SAMSUNG, Nidec, Xiaomi, GREE, Midea, WOLONG, amazon, etc. We manufacture type of Ferrite Magnet and Neodymium(NdFeB) Magnet for electric motor, widely used in the field of new generation consumer electronics and energy-saving home appliances.

Just tell us your applied industry, product performance parameters, quantity and size, we will recommend the most suitable magnet for you.

Indija ’s Tržište energije vjetra

Indija je jedno od najbrže rastućih tržišta energije vjetra na svijetu , s velikim brojem vjetroturbina instaliranih diljem zemlje . Vlada je postavila ambiciozne ciljeve za proizvodnju obnovljive energije , uključujući snagu vjetra , i implementirao je politike koje potiču razvoj projekata vjetroelektrana . Očekuje se da će kapacitet vjetroelektrana u Indiji dosegnuti 60 GW do 2022 , a očekuje se da će tržište vjetroturbina rasti po CAGR-u od 6,4% od 2020. do 2027. . Očekuje se da će rastuća potražnja za čistom energijom i povoljno političko okruženje u Indiji potaknuti potražnju za vjetroturbinama , uključujući one koji koriste NdFeB magnete.

Oblici i veličine NdFeB magneta

NdFeB magneti dolaze u različitim oblicima i veličinama, ovisno o zahtjevima primjene. Za generatore vjetroturbina najčešće korišteni oblici su blokovi, prstenovi i lukovi/segmenti. Blok magneti se obično koriste u generatorima s izravnim pogonom, gdje daju visok moment i kompaktan dizajn. Prstenasti magneti koriste se u generatorima s poluizravnim pogonom, gdje daju veliku brzinu vrtnje i malu silu zupčanja. Segmentni magneti koriste se iu generatorima s izravnim i poluizravnim pogonom, gdje daju visok moment i fleksibilan dizajn. Veličine NdFeB magneta mogu se kretati od milimetara do centimetara, ovisno o zahtjevima primjene.

Ocjene performansi NdFeB magneta

Ocjene performansi NdFeB magneta kreću se od N35 do N52 ili s H, SH, UH, s višim ocjenama koje osiguravaju veću magnetsku snagu i bolju izvedbu u ekstremnim uvjetima. U generatorima vjetroturbina obično se koriste stupnjevi višeg učinka zbog oštrog radnog okruženja i potrebe za velikim okretnim momentom. NdFeB magneti s ocjenom učinka N42 obično se koriste u generatorima vjetroturbina zbog svoje velike magnetske čvrstoće i izvrsne temperaturne stabilnosti.

Tržišni izgledi za NdFeB magnete u Indiji

Očekuje se da će tržište energije vjetra u Indiji brzo rasti, potaknuto ambicioznim vladinim ciljevima obnovljive energije i povoljnim političkim okruženjem. Očekuje se da će potražnja za generatorima vjetroturbina, uključujući one koji koriste NdFeB magnete, značajno porasti u nadolazećim godinama. Rastuća svijest o prednostima obnovljive energije i potrebi smanjenja emisije ugljika dodatno će potaknuti potražnju za vjetroturbinama. Očekuje se da će tržište energije vjetra u Indiji ponuditi značajne mogućnosti proizvođačima NdFeB magneta, posebno onima koji mogu ponuditi magnete visoke kvalitete po konkurentnoj cijeni.

Prednosti tvrtke Zhejiang Zhongke Magnetic Industry Co., Ltd.

Zhejiang Zhongke Magnetic Industry Co., Ltd. je vodeći proizvođač NdFeB magneta u Kini, sa snažnom prisutnošću u industriji energije vjetra. Tvrtka ima vrhunski proizvodni pogon i tim iskusnih stručnjaka koji su posvećeni isporuci magneta visoke kvalitete. Snage tvrtke u proizvodnji generatora vjetroturbina uključuju:

1. Visokokvalitetni magneti: Zhejiang Zhongke Magnetic Industry Co., Ltd. poznat je po svojim visokokvalitetnim NdFeB magnetima, koji se proizvode pomoću najnovije tehnologije i strogih mjera kontrole kvalitete. Magneti su dizajnirani da izdrže ekstremne uvjete i daju visok okretni moment i pouzdanost. Izvršit će potpuno standardno testiranje ili dodati sadržaj testiranja prema zahtjevu kupca prije tvorničke isporuke i svaka će pošiljka biti s izvješćima o ispitivanju kako bi se osigurala kvaliteta magneta.

2. Konkurentne cijene: Tvrtka nudi konkurentne cijene za svoje NdFeB magnete, što ih čini privlačnom opcijom za proizvođače vjetroturbina.

3. Snažan lanac opskrbe: Zhejiang Zhongke Magnetic Industry Co., Ltd. ima snažan lanac opskrbe koji osigurava pravovremenu isporuku magneta svojim kupcima.

4. Tehnička stručnost: Tvrtka ima tim tehničkih stručnjaka koji svojim klijentima pružaju podršku i smjernice, osiguravajući da dobiju najbolja rješenja za svoje potrebe.

NdFeB magneti naširoko se koriste u generatorima vjetroturbina u Indiji zbog svoje velike magnetske snage i izvrsnih performansi. Dolaze u različitim oblicima, veličinama i stupnjevima izvedbe, ovisno o zahtjevima primjene. Očekuje se da će tržište energije vjetra u Indiji brzo rasti, pružajući značajne mogućnosti za proizvođače NdFeB magneta. Zhejiang Zhongke Magnetic Industry Co., Ltd. je vodeći proizvođač NdFeB magneta u Kini, sa snažnom prisutnošću u industriji energije vjetra. Snage tvrtke u proizvodnji generatora vjetroturbina uključuju visokokvalitetne magnete, konkurentne cijene, snažan opskrbni lanac i tehničku stručnost.

Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances.

The company's current production process of permanent ferrite magnets is as follows: the purchased pre-fired materials are mixed according to their own formula and ingredients, and after being ball milled by a ball mill, ferrite is produced through steps such as precipitation, wet pressing, sintering, and grinding. Body magnetic tiles, ferrite magnets and other finished products. The specific production process flow chart is as follows:

The strontium ferrite calcined material (the main component is SrFe12O19) is mixed with calcium carbonate, silicon dioxide, strontium carbonate, lanthanum oxide, cobalt oxide and other ingredients according to the formula ratio.

The raw materials are added with water and pulverized by a ball mill to form a slurry, which is placed in a sedimentation tower for precipitation.

The dehydrated material formed by precipitation is made into a green body through an automatic press in a normal air environment.

The raw body is sintered at high temperature into a mature body through a wet-pressed magnetic tile electric-fired roller kiln or a wet-pressed magnetic steel gas-fired roller kiln.

The cooked blank is processed by a fully automatic grinding machine processing line to form a finished product.

The magnetic properties, appearance, size and other indicators of the magnets are inspected, packed and put into storage.

The company has applied and improved a number of advanced technologies in the industry, such as high-performance ferrite slurry stabilization technology and secondary ball milling batching technology, which has solved the quantitative problem of material added in the preparation process. And we use double coupling dispersion and fine grinding to overcome the problems of slurry agglomeration and particle size distribution consistency. The performance of the slurry obtained in the ball milling process is more stable, which reduces the unit operating time of the ball milling equipment, improves product quality, and reduces production costs.

The company uses a unique new green release agent independently developed to prepare magnetic tiles. The new green release agent is an organic combination of microbial technology and surface release treatment technology, which can degrade oil molecules, reduce the oil content of the release agent, and restore the surface. active lipophilic factor. The product is combined with the surface release process, and the release effect of the magnetic tile is improved through a new release agent, and the surface finish of the blank is improved. The demoulding technology has the characteristics of simple preparation method and convenient application, and improves production efficiency.

By transforming the sintering preheating system equipment, the company reduces the water content of the sintered green body in the kiln, greatly reduces the waste rate caused by factors such as cracking and lack of oxygen during sintering, and improves the sintering density and mechanical strength of the product. Obtain good microstructure and magnet properties. The company has also realized the sintering base temperature that products with different performances can adapt to through formula adjustment. Products with different specifications, sizes and performances can be co-fired at the same temperature, which significantly improves the production efficiency of the sintering process. In addition, in terms of veneer loading and billet loading, the company has adopted a bulk stacking method that conforms to the company's product features of small shape and light weight after many tests, realizing heavy veneer loading, good sintering atmosphere, and high sintering yield. good effect.

By optimizing the parameters of grinding machines and other processing equipment and improving the process technology, the company has improved the consistency of product thickness to ≤0.02MM within L30MM and ≤0.04MM within L50MM, and has mastered the technology of three-phase motor magnets produced by grinding tooling. Breakthroughs have been made in technical difficulties in the industry, such as product precision and stable equipment performance, and certain innovations have been achieved in technology and equipment.

The company's magnetic tile products are developing in the direction of high efficiency, low consumables, and low energy consumption. For example, through atomic substitution and compound doping, the rare earth-free ZK-5B high-performance motor magnetic tile independently developed by the company reduces the coagulation of magnetic powder, improves the orientation effect, improves the material performance and reduces the production cost by using strong magnetic field to suppress and adding a double dispersant.