Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

Feritni magneti, također poznati kao keramički magneti, intenzivno se koriste u mnogim primjenama zbog svoje relativno niske cijene, visokih magnetskih svojstava i izvrsne otpornosti na koroziju. Među različitim primjenama, feritni magneti naširoko se koriste u električnim motorima, posebno onima koji pokreću perilice rublja. Predstavit će primjenu feritnih magneta u motoru perilice rublja, uključujući performanse, dimenzije, temperaturnu otpornost, otpornost na demagnetizaciju i zahtjeve za ispitivanje. Također analizira trend globalnog tržišta perilica rublja, posebno u regiji jugoistočne Azije i Indiji, te ističe prednosti Zhejiang Zhongke Magnetic Industry Co., Ltd. (Zhongke) u proizvodnji feritnih magneta.

+86-15857968349

+86-15857968349

Primjena feritnih magneta u motoru perilice rublja

Elektromotor perilice rublja pretvara električnu energiju u mehaničku i pokreće mješalicu ili bubanj za pranje rublja. Feritni magneti bitne su komponente motora perilice rublja koje osiguravaju magnetsko polje potrebno za rad motora.

Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

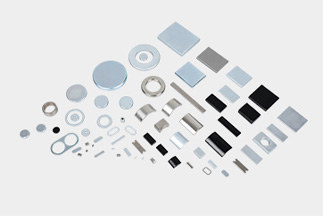

With a strong engineer team and professional production lines, Zhongke can design and produce magnet in all shapes according to your needs.

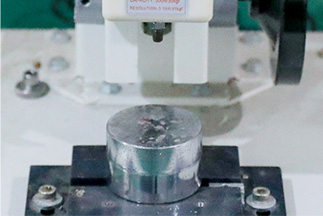

If you are not sure about the performance parameters of the product, you can send us a sample, we will do a professional test, determine the performance parameters and issue a report for your reference.

Exclusive customer service 7x24 hours to get professional help, make an appointment with a professional technical engineer to get a comprehensive solution.

Publicly traded listed magnet company in China. Our magnet supplied to many large, medium-scale customers including SAMSUNG, Nidec, Xiaomi, GREE, Midea, WOLONG, amazon, etc. We manufacture type of Ferrite Magnet and Neodymium(NdFeB) Magnet for electric motor, widely used in the field of new generation consumer electronics and energy-saving home appliances.

Just tell us your applied industry, product performance parameters, quantity and size, we will recommend the most suitable magnet for you.

Izvođenje

Magnetska izvedba feritnih magneta za motore perilica rublja mora ispunjavati specifične zahtjeve za okretni moment, brzinu i energetsku učinkovitost. Koercitivnost magneta određuje jakost magnetskog polja, a time i okretni moment koji motor može proizvesti. Magnetska remanencija magneta određuje brzinu kojom motor može raditi, a produkt magnetske energije određuje energetsku učinkovitost motora. Obično će se koristiti stupanj 9H, 9B, 12H, 12B (može se pozvati na tablicu s podacima u nastavku).

| Karakteristike magneta s feritnim lukom ispod 23 ℃ /-2 ℃ | |||||

| Razred | Preostala gustoća magnetskog toka (Br) | Magnetska prisilna sila (Hcb) | Intrinzična prisila (Hcj) | Maksimalni energetski proizvod (BH) max | Gustoća |

| ZK-12H | 4300±150 (Gs) | 4000±150 (Oe) | 5200±150(Oe) | 4,6±0,2 (MGOe) | 4,9-5,1 (g/cm³) |

| 430±15(mT) | 319±12(KA/m) | 414±12(KA/m) | 36,8±1,6(KJ/m³) | ||

| ZK-12B | 4550±150 (Gs) | 4050±150(Oe) | 4550±150(Oe) | 4,7±0,2 (MGOe) | 4,9-5,1 (g/cm³) |

| 455±15(mT) | 323±12(KA/m) | 362±12(KA/m) | 437,6±1,6(KJ/m³) | ||

| ZK-9H | 4250±100 (Gs) | 3750±150(Oe) | 4650±150(Oe) | 4,1±0,2 (MGOe) | 4,9-5,1 (g/cm³) |

| 425±10(mT) | 298±12(KA/m) | 370±12(KA/m) | 33±1,6(KJ/m³) | ||

| ZK-9B | 4300±100 (Gs) | 3900±150(Oe) | 4300±150 (Oe) | 4,4±0,2 (MGOe) | 4,9-5,1 (g/cm³) |

| 430±10(mT) | 311±12(KA/m) | 342±12(KA/m) | 35,2±1,6(KJ/m³) | ||

Dimenzije

Dimenzije feritnih magneta koji se koriste u motorima perilica rublja razlikuju se ovisno o snazi i veličini motora. Tipično, magneti su pravokutni ili prstenasti, s dimenzijama u rasponu od nekoliko milimetara do desetaka centimetara.

Otpornost na temperaturu

Feritni magneti za motore perilica rublja moraju izdržati visoke temperature jer rade pri velikim brzinama. Maksimalna radna temperatura magneta obično je između 200°C i 300°C.

Otpornost na demagnetizaciju

Feritni magneti za motore perilica rublja moraju biti otporni na demagnetizaciju uzrokovanu temperaturom, mehaničkim udarima ili vibracijama. Unutarnja koercitivnost magneta i njihov dizajn magnetskog kruga određuju njihovu otpornost na demagnetizaciju.

Zahtjevi za testiranje

Kako bi se osigurala kvaliteta i učinkovitost feritnih magneta koji se koriste u motorima perilica rublja, moraju se provesti razna ispitivanja. Najčešći test je magnetsko mjerenje remanencije, koercitivnosti i produkta magnetske energije. Ostali testovi uključuju mjerenje krivulje demagnetizacije, test temperaturnog demagnetiziranja i test udarca i vibracija.

Globalni tržišni trend perilica rublja

Tržište perilica rublja raste u cijelom svijetu, potaknuto rastućom urbanizacijom, povećanjem raspoloživog dohotka i promjenom načina života. Prema izvješću Statista, veličina globalnog tržišta perilica rublja bila je procijenjena na 51,98 milijardi USD u 2018. i predviđa se da će dosegnuti 80,87 milijardi USD do 2025., rastući uz CAGR od 6,5% od 2019. do 2025.

Očekuje se da će tržište perilica rublja u regiji jugoistočne Azije rasti po CAGR-u od 5,2% od 2020. do 2025., potaknuto sve većom potražnjom potrošača, širenjem proizvodne baze i vladinim inicijativama za razvoj proizvodnog sektora. Prema drugom izvješću Statiste, veličina tržišta perilica rublja u Indiji procijenjena je na 1,64 milijarde USD u 2020. i očekuje se da će rasti po CAGR-u od 5,8% od 2021. do 2028., potaknuto sve većom urbanizacijom, povećanjem populacije srednje klase i rastuća svijest o higijeni i čistoći.

Prednosti Zhongkea u proizvodnji feritnih magneta

Zhongke je vodeći proizvođač feritnih magneta u Kini, sa snažnim fokusom na tehnološke inovacije, kontrolu kvalitete i zadovoljstvo kupaca. Zhongkeovi feritni magneti za motore perilica rublja imaju sljedeće prednosti:

1. Visoka magnetska izvedba: Zhongkeovi feritni magneti imaju visoku koercitivnost i produkt magnetske energije, osiguravajući okretni moment, brzinu i energetsku učinkovitost motora.

2. Dosljedna kvaliteta: Zhongke koristi naprednu tehnologiju proizvodnje i sustav upravljanja kvalitetom kako bi osigurao dosljednu i pouzdanu kvalitetu svojih feritnih magneta.

3. Mogućnost prilagodbe: Zhongke može prilagoditi dimenzije, oblike i magnetska svojstva svojih feritnih magneta kako bi zadovoljio specifične zahtjeve kupaca.

4. Konkurentne cijene: Zhongke nudi konkurentne cijene za svoje feritne magnete bez ugrožavanja kvalitete i performansi.

Feritni magneti bitne su komponente motora perilice rublja, osiguravajući magnetsko polje potrebno za rad motora. Magnetska izvedba, dimenzije, otpornost na temperaturu, otpornost na demagnetizaciju i zahtjevi za ispitivanje feritnih magneta za motore perilica moraju ispunjavati posebne zahtjeve. Globalno tržište perilica rublja raste, posebno u regiji jugoistočne Azije i Indiji. Zhongke ima nekoliko prednosti u proizvodnji feritnih magneta za motore perilica rublja, uključujući visoku magnetsku učinkovitost, dosljednu kvalitetu, mogućnost prilagođavanja i konkurentne cijene.

Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances.

The company's current production process of permanent ferrite magnets is as follows: the purchased pre-fired materials are mixed according to their own formula and ingredients, and after being ball milled by a ball mill, ferrite is produced through steps such as precipitation, wet pressing, sintering, and grinding. Body magnetic tiles, ferrite magnets and other finished products. The specific production process flow chart is as follows:

The strontium ferrite calcined material (the main component is SrFe12O19) is mixed with calcium carbonate, silicon dioxide, strontium carbonate, lanthanum oxide, cobalt oxide and other ingredients according to the formula ratio.

The raw materials are added with water and pulverized by a ball mill to form a slurry, which is placed in a sedimentation tower for precipitation.

The dehydrated material formed by precipitation is made into a green body through an automatic press in a normal air environment.

The raw body is sintered at high temperature into a mature body through a wet-pressed magnetic tile electric-fired roller kiln or a wet-pressed magnetic steel gas-fired roller kiln.

The cooked blank is processed by a fully automatic grinding machine processing line to form a finished product.

The magnetic properties, appearance, size and other indicators of the magnets are inspected, packed and put into storage.

The company has applied and improved a number of advanced technologies in the industry, such as high-performance ferrite slurry stabilization technology and secondary ball milling batching technology, which has solved the quantitative problem of material added in the preparation process. And we use double coupling dispersion and fine grinding to overcome the problems of slurry agglomeration and particle size distribution consistency. The performance of the slurry obtained in the ball milling process is more stable, which reduces the unit operating time of the ball milling equipment, improves product quality, and reduces production costs.

The company uses a unique new green release agent independently developed to prepare magnetic tiles. The new green release agent is an organic combination of microbial technology and surface release treatment technology, which can degrade oil molecules, reduce the oil content of the release agent, and restore the surface. active lipophilic factor. The product is combined with the surface release process, and the release effect of the magnetic tile is improved through a new release agent, and the surface finish of the blank is improved. The demoulding technology has the characteristics of simple preparation method and convenient application, and improves production efficiency.

By transforming the sintering preheating system equipment, the company reduces the water content of the sintered green body in the kiln, greatly reduces the waste rate caused by factors such as cracking and lack of oxygen during sintering, and improves the sintering density and mechanical strength of the product. Obtain good microstructure and magnet properties. The company has also realized the sintering base temperature that products with different performances can adapt to through formula adjustment. Products with different specifications, sizes and performances can be co-fired at the same temperature, which significantly improves the production efficiency of the sintering process. In addition, in terms of veneer loading and billet loading, the company has adopted a bulk stacking method that conforms to the company's product features of small shape and light weight after many tests, realizing heavy veneer loading, good sintering atmosphere, and high sintering yield. good effect.

By optimizing the parameters of grinding machines and other processing equipment and improving the process technology, the company has improved the consistency of product thickness to ≤0.02MM within L30MM and ≤0.04MM within L50MM, and has mastered the technology of three-phase motor magnets produced by grinding tooling. Breakthroughs have been made in technical difficulties in the industry, such as product precision and stable equipment performance, and certain innovations have been achieved in technology and equipment.

The company's magnetic tile products are developing in the direction of high efficiency, low consumables, and low energy consumption. For example, through atomic substitution and compound doping, the rare earth-free ZK-5B high-performance motor magnetic tile independently developed by the company reduces the coagulation of magnetic powder, improves the orientation effect, improves the material performance and reduces the production cost by using strong magnetic field to suppress and adding a double dispersant.