Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

Neodimijski željezo-bor (NdFeB) magneti, također poznati kao magneti rijetkih zemalja, naširoko se koriste u raznim industrijama, uključujući akustiku. Poznati su po svojim iznimnim magnetskim svojstvima i visokoj koercitivnosti. NdFeB magneti nude snažna magnetska polja u malim veličinama što ih čini idealnim za korištenje u akustičnim aplikacijama gdje je prostor ograničen. Ovaj članak pružit će pregled primjene NdFeB magneta u akustici, uključujući njihov oblik, veličinu, toleranciju, izvedbu, zahtjeve premazivanja i tržišne izglede u Vijetnamu i Indiji. Osim toga, analizirat ćemo proizvodne prednosti Zhejiang Zhongke Magnetic Industry Co., Ltd.

+86-15857968349

+86-15857968349

NdFeB magneti u akustičkim primjenama:

Akustička industrija koristi NdFeB magnete u različitim primjenama, uključujući zvučnike, mikrofone, slušna pomagala i slušalice. NdFeB magneti se također koriste u audio opremi i glazbenim instrumentima. Njihova jedinstvena svojstva, uključujući veliku snagu magnetskog polja i visoku koercitivnost, čine ih idealnim za mnoge akustičke primjene.

Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

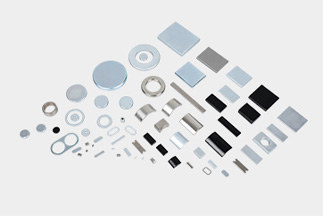

With a strong engineer team and professional production lines, Zhongke can design and produce magnet in all shapes according to your needs.

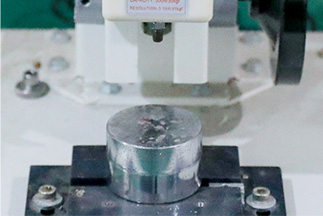

If you are not sure about the performance parameters of the product, you can send us a sample, we will do a professional test, determine the performance parameters and issue a report for your reference.

Exclusive customer service 7x24 hours to get professional help, make an appointment with a professional technical engineer to get a comprehensive solution.

Publicly traded listed magnet company in China. Our magnet supplied to many large, medium-scale customers including SAMSUNG, Nidec, Xiaomi, GREE, Midea, WOLONG, amazon, etc. We manufacture type of Ferrite Magnet and Neodymium(NdFeB) Magnet for electric motor, widely used in the field of new generation consumer electronics and energy-saving home appliances.

Just tell us your applied industry, product performance parameters, quantity and size, we will recommend the most suitable magnet for you.

Oblik, veličina i tolerancija:

NdFeB magneti koji se koriste u akustičnim aplikacijama dostupni su u nizu oblika i veličina kako bi odgovarali različitim zahtjevima. Najčešće korišteni oblik je cilindrični oblik promjera od 3 mm do 40 mm i debljine od 1 mm do 30 mm. NdFeB magneti koji se koriste u slušalicama obično su mali, s promjerom manjim od 10 mm. U međuvremenu, zvučnici koriste veće magnete, obično promjera od 10 mm do 40 mm. NdFeB magneti koji se koriste u mikrofonima obično su manji od onih koji se koriste u zvučnicima i obično imaju promjer od 3 mm ili manje. NdFeB magneti za akustičke primjene zahtijevaju visoke razine tolerancije kako bi ispunili specifične zahtjeve, a razina tolerancije kreće se od /-0,05 mm do /-0,1 mm.

Izvođenje:

NdFeB magneti koji se koriste u akustičnim aplikacijama moraju imati izvrsna magnetska svojstva. To uključuje visok produkt maksimalne energije, visoku koercitivnu silu i visoku gustoću magnetskog toka. Maksimalni energetski proizvod za NdFeB magnete koji se koriste u akustičnim aplikacijama kreće se od 32MGOe do 55MGOe. Koercitivnost se kreće od 11 000 Oe do 14 000 Oe. Gustoća magnetskog toka kreće se od 12 000 G do 15 000 G.

Zahtjevi za premazivanje:

NdFeB magneti su presvučeni kako bi se spriječila korozija, posebno kada su izloženi vlažnom okruženju. Premaz također pruža sloj zaštite od oštećenja tijekom rukovanja i postavljanja. Uobičajeni materijali za premazivanje koji se koriste za NdFeB magnete uključuju nikal, cink, zlato i epoksid. Premazi od cinka i nikla najčešće se koriste zbog niske cijene i visoke razine zaštite.

Tržišni izgledi u Vijetnamu i Indiji:

Tržišta za NdFeB magnete u Vijetnamu i Indiji doživjela su stalan rast tijekom godina. Dvije zemlje imaju značajan potencijal u akustičnoj industriji i kao takve, postoji sve veća potražnja za NdFeB magnetima na tim tržištima. U Vijetnamu, potražnju za NdFeB magnetima pokreće automobilska industrija, gdje se koriste u električnim automobilima, električnim prozorima i motorima. Tržište u Indiji doživljava rast zbog povećane primjene NdFeB magneta u potrošačkoj elektronici, zrakoplovnoj i automobilskoj industriji.

Prednosti proizvodnje tvrtke Zhejiang Zhongke Magnetic Industry Co., Ltd:

Zhejiang Zhongke Magnetic Industry Co., Ltd. je vodeći proizvođač NdFeB magneta u Kini. Tvrtka ima značajno iskustvo u proizvodnji NdFeB magneta za razne industrije, uključujući akustiku. Proizvodni pogon tvrtke opremljen je modernim objektima, uključujući naprednu proizvodnu opremu, strojeve za testiranje i stanice za inspekciju. Koristeći naprednu tehnologiju, tvrtka proizvodi visokokvalitetne NdFeB magnete visoke razine preciznosti i dosljednosti. Tvrtka je razvila strogi sustav kontrole kvalitete koji osigurava kontinuirano poboljšanje kvalitete svojih proizvoda. Visokokvalitetni NdFeB magneti koje proizvodi Zhejiang Zhongke Magnetic Industry Co., Ltd. stekli su povjerenje kupaca diljem svijeta.

NdFeB magneti imaju širok raspon primjena u akustičkoj industriji, uključujući zvučnike, mikrofone, slušna pomagala i slušalice. Njihova jedinstvena svojstva, uključujući visoku jakost magnetskog polja i visoku koercitivnost, čine ih idealnim za korištenje u akustičnim aplikacijama. NdFeB magneti koji se koriste u akustici dolaze u različitim oblicima, veličinama i razinama tolerancije, a tržišni izgledi u Vijetnamu i Indiji su obećavajući. Zhejiang Zhongke Magnetic Industry Co., Ltd., sa svojom naprednom tehnologijom i proizvodnim mogućnostima, nudi visokokvalitetne NdFeB magnete koji zadovoljavaju potrebe kupaca u akustičkoj industriji i šire.

Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances.

The company's current production process of permanent ferrite magnets is as follows: the purchased pre-fired materials are mixed according to their own formula and ingredients, and after being ball milled by a ball mill, ferrite is produced through steps such as precipitation, wet pressing, sintering, and grinding. Body magnetic tiles, ferrite magnets and other finished products. The specific production process flow chart is as follows:

The strontium ferrite calcined material (the main component is SrFe12O19) is mixed with calcium carbonate, silicon dioxide, strontium carbonate, lanthanum oxide, cobalt oxide and other ingredients according to the formula ratio.

The raw materials are added with water and pulverized by a ball mill to form a slurry, which is placed in a sedimentation tower for precipitation.

The dehydrated material formed by precipitation is made into a green body through an automatic press in a normal air environment.

The raw body is sintered at high temperature into a mature body through a wet-pressed magnetic tile electric-fired roller kiln or a wet-pressed magnetic steel gas-fired roller kiln.

The cooked blank is processed by a fully automatic grinding machine processing line to form a finished product.

The magnetic properties, appearance, size and other indicators of the magnets are inspected, packed and put into storage.

The company has applied and improved a number of advanced technologies in the industry, such as high-performance ferrite slurry stabilization technology and secondary ball milling batching technology, which has solved the quantitative problem of material added in the preparation process. And we use double coupling dispersion and fine grinding to overcome the problems of slurry agglomeration and particle size distribution consistency. The performance of the slurry obtained in the ball milling process is more stable, which reduces the unit operating time of the ball milling equipment, improves product quality, and reduces production costs.

The company uses a unique new green release agent independently developed to prepare magnetic tiles. The new green release agent is an organic combination of microbial technology and surface release treatment technology, which can degrade oil molecules, reduce the oil content of the release agent, and restore the surface. active lipophilic factor. The product is combined with the surface release process, and the release effect of the magnetic tile is improved through a new release agent, and the surface finish of the blank is improved. The demoulding technology has the characteristics of simple preparation method and convenient application, and improves production efficiency.

By transforming the sintering preheating system equipment, the company reduces the water content of the sintered green body in the kiln, greatly reduces the waste rate caused by factors such as cracking and lack of oxygen during sintering, and improves the sintering density and mechanical strength of the product. Obtain good microstructure and magnet properties. The company has also realized the sintering base temperature that products with different performances can adapt to through formula adjustment. Products with different specifications, sizes and performances can be co-fired at the same temperature, which significantly improves the production efficiency of the sintering process. In addition, in terms of veneer loading and billet loading, the company has adopted a bulk stacking method that conforms to the company's product features of small shape and light weight after many tests, realizing heavy veneer loading, good sintering atmosphere, and high sintering yield. good effect.

By optimizing the parameters of grinding machines and other processing equipment and improving the process technology, the company has improved the consistency of product thickness to ≤0.02MM within L30MM and ≤0.04MM within L50MM, and has mastered the technology of three-phase motor magnets produced by grinding tooling. Breakthroughs have been made in technical difficulties in the industry, such as product precision and stable equipment performance, and certain innovations have been achieved in technology and equipment.

The company's magnetic tile products are developing in the direction of high efficiency, low consumables, and low energy consumption. For example, through atomic substitution and compound doping, the rare earth-free ZK-5B high-performance motor magnetic tile independently developed by the company reduces the coagulation of magnetic powder, improves the orientation effect, improves the material performance and reduces the production cost by using strong magnetic field to suppress and adding a double dispersant.