Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

Kako se svijet pomiče prema održivom razvoju, potražnja za novim energetskim vozilima strahovito raste. Jedna od ključnih komponenti ovih vozila je neodimijski željezo-bor (NdFeB) magnet koji igra ključnu ulogu u njihovim performansama. NdFeB magneti imaju neusporedivu snagu, pouzdanost i otpornost na visoke temperature, što ih čini idealnim izborom za različite primjene u automobilskom sektoru. U ovom ćemo članku istražiti različite dijelove novog energetskog vozila u kojem se koriste NdFeB magneti, njihove stupnjeve izvedbe, oblike, veličine i njihove odgovarajuće primjene. Osim toga, analizirat ćemo izglede tržišta i konkurentsku prednost Zhejiang Zhongke Magnetic Industry Co., Ltd.

NdFeB magneti primijenjeni u novim energetskim vozilima

+86-15857968349

+86-15857968349

1. Električni motor

NdFeB magneti se intenzivno koriste u električnim motorima novih energetskih vozila zbog svoje velike magnetske snage i otpornosti na demagnetizaciju. Koriste se za stvaranje magnetskog polja potrebnog za rotaciju rotora i osiguravanje potrebnog momenta za kretanje vozila. Performanse elektromotora značajno ovise o magnetskim svojstvima korištenog NdFeB magneta.

Razred performansi: N35-N52, 35M-50M, 30H-48H, 30SH-45SH, 28UH-40UH, 28EH-38EH, 28AH-35AH

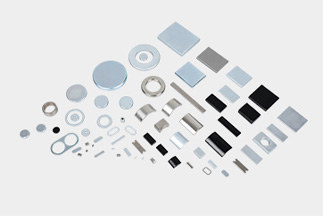

Oblik i veličina: luk, prsten, blok i prilagođene veličine

Primjena: Rotor elektromotora

Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

With a strong engineer team and professional production lines, Zhongke can design and produce magnet in all shapes according to your needs.

If you are not sure about the performance parameters of the product, you can send us a sample, we will do a professional test, determine the performance parameters and issue a report for your reference.

Exclusive customer service 7x24 hours to get professional help, make an appointment with a professional technical engineer to get a comprehensive solution.

Publicly traded listed magnet company in China. Our magnet supplied to many large, medium-scale customers including SAMSUNG, Nidec, Xiaomi, GREE, Midea, WOLONG, amazon, etc. We manufacture type of Ferrite Magnet and Neodymium(NdFeB) Magnet for electric motor, widely used in the field of new generation consumer electronics and energy-saving home appliances.

Just tell us your applied industry, product performance parameters, quantity and size, we will recommend the most suitable magnet for you.

2. Električni servo upravljač

Sustavi električnog servoupravljača (EPS) koriste NdFeB magnete za otkrivanje kuta upravljanja i okretnog momenta za pružanje potrebne pomoći vozaču. Snaga korištenih magneta izravno utječe na preciznost i odziv EPS sustava.

Ocjena performansi: N35-N52, 35M-50M, 30H-48H, 30SH-45SH, 28UH-40UH, 28EH-38EH

Oblik i veličina: luk, prsten, blok i prilagođene veličine

Primjena: EPS motor

3. Hibridni prijenos

NdFeB magneti se također koriste u hibridnom prijenosu novih energetskih vozila za generiranje potrebnog magnetskog polja za prijenos snage, čime se poboljšava učinkovitost prijenosa i poboljšava iskustvo vožnje.

Razred performansi: N35-N52, 35M-50M, 30H-48H, 30SH-45SH, 28UH-40UH, 28EH-38EH, 28AH-35AH

Oblik i veličina: luk, prsten, blok i prilagođene veličine

Primjena: hibridni prijenosni sustav

4. Sustav upravljanja baterijom

Sustav upravljanja baterijom (BMS) bitan je dio novog energetskog vozila koji prati i kontrolira performanse baterije, uključujući stope punjenja i pražnjenja, temperaturu i cjelokupno zdravlje. NdFeB magneti se koriste u BMS-u za poboljšanje preciznosti i odziva senzora.

Razred performansi: N35-N52, 35M-50M, 30H-48H, 30SH-45SH, 28UH-40UH, 28EH-38EH, 28AH-35AH

Oblik i veličina: Blok, cilindar i prilagođene veličine

Primjena: BMS

Predviđanje tržišta

Kako globalna potražnja za električnim i hibridnim vozilima raste, očekuje se da će tržište za NdFeB magnete značajno rasti. Prema izvješću Allied Market Researcha, predviđa se da će globalno tržište NdFeB magneta dosegnuti 28,7 milijardi dolara do 2027., rastući uz CAGR od 8,9% tijekom predviđenog razdoblja. Očekuje se da će automobilski sektor biti najveći potrošač NdFeB magneta zbog rastuće potražnje za novim energetskim vozilima diljem svijeta.

Konkurentska prednost tvrtke Zhejiang Zhongke Magnetic Industry Co., Ltd.

Zhejiang Zhongke Magnetic Industry Co., Ltd. je jedan od vodećih proizvođača NdFeB magneta u Kini, specijaliziran za visokoučinkovite kvalitete za razne automobilske primjene. Tvrtka ima konkurentsku prednost zbog:

1. Napredna tehnologija proizvodnje: Zhejiang Zhongke Magnetic Industry Co., Ltd. koristi naprednu proizvodnu tehnologiju i opremu za proizvodnju visokokvalitetnih NdFeB magneta koji zadovoljavaju međunarodne standarde.

2. Opsežan asortiman proizvoda: tvrtka nudi širok raspon NdFeB magneta u različitim oblicima, veličinama i stupnjevima performansi kako bi zadovoljila različite potrebe automobilske industrije.

3. Snažne mogućnosti istraživanja i razvoja: Zhejiang Zhongke Magnetic Industry Co., Ltd. ima snažan tim za istraživanje i razvoj koji se fokusira na razvoj inovativnih NdFeB magneta s višim magnetskim svojstvima i poboljšanim performansama.

Zaključak

NdFeB magneti su vitalne komponente novih energetskih vozila zbog svojih vrhunskih svojstava i visoke pouzdanosti. Koriste se u raznim dijelovima vozila, uključujući električne motore, EPS sustave, hibridne mjenjače i sustave upravljanja baterijom, kako bi se poboljšala njihova izvedba. Očekuje se da će tržište za NdFeB magnete značajno rasti zbog sve veće potražnje za novim energetskim vozilima diljem svijeta. Zhejiang Zhongke Magnetic Industry Co., Ltd. pouzdan je partner u automobilskoj industriji koji nudi visokokvalitetne NdFeB magnete i neusporedivu korisničku podršku.

Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances.

The company's current production process of permanent ferrite magnets is as follows: the purchased pre-fired materials are mixed according to their own formula and ingredients, and after being ball milled by a ball mill, ferrite is produced through steps such as precipitation, wet pressing, sintering, and grinding. Body magnetic tiles, ferrite magnets and other finished products. The specific production process flow chart is as follows:

The strontium ferrite calcined material (the main component is SrFe12O19) is mixed with calcium carbonate, silicon dioxide, strontium carbonate, lanthanum oxide, cobalt oxide and other ingredients according to the formula ratio.

The raw materials are added with water and pulverized by a ball mill to form a slurry, which is placed in a sedimentation tower for precipitation.

The dehydrated material formed by precipitation is made into a green body through an automatic press in a normal air environment.

The raw body is sintered at high temperature into a mature body through a wet-pressed magnetic tile electric-fired roller kiln or a wet-pressed magnetic steel gas-fired roller kiln.

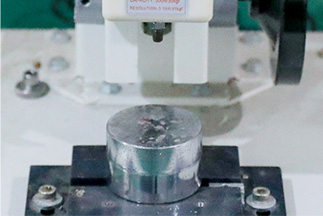

The cooked blank is processed by a fully automatic grinding machine processing line to form a finished product.

The magnetic properties, appearance, size and other indicators of the magnets are inspected, packed and put into storage.

The company has applied and improved a number of advanced technologies in the industry, such as high-performance ferrite slurry stabilization technology and secondary ball milling batching technology, which has solved the quantitative problem of material added in the preparation process. And we use double coupling dispersion and fine grinding to overcome the problems of slurry agglomeration and particle size distribution consistency. The performance of the slurry obtained in the ball milling process is more stable, which reduces the unit operating time of the ball milling equipment, improves product quality, and reduces production costs.

The company uses a unique new green release agent independently developed to prepare magnetic tiles. The new green release agent is an organic combination of microbial technology and surface release treatment technology, which can degrade oil molecules, reduce the oil content of the release agent, and restore the surface. active lipophilic factor. The product is combined with the surface release process, and the release effect of the magnetic tile is improved through a new release agent, and the surface finish of the blank is improved. The demoulding technology has the characteristics of simple preparation method and convenient application, and improves production efficiency.

By transforming the sintering preheating system equipment, the company reduces the water content of the sintered green body in the kiln, greatly reduces the waste rate caused by factors such as cracking and lack of oxygen during sintering, and improves the sintering density and mechanical strength of the product. Obtain good microstructure and magnet properties. The company has also realized the sintering base temperature that products with different performances can adapt to through formula adjustment. Products with different specifications, sizes and performances can be co-fired at the same temperature, which significantly improves the production efficiency of the sintering process. In addition, in terms of veneer loading and billet loading, the company has adopted a bulk stacking method that conforms to the company's product features of small shape and light weight after many tests, realizing heavy veneer loading, good sintering atmosphere, and high sintering yield. good effect.

By optimizing the parameters of grinding machines and other processing equipment and improving the process technology, the company has improved the consistency of product thickness to ≤0.02MM within L30MM and ≤0.04MM within L50MM, and has mastered the technology of three-phase motor magnets produced by grinding tooling. Breakthroughs have been made in technical difficulties in the industry, such as product precision and stable equipment performance, and certain innovations have been achieved in technology and equipment.

The company's magnetic tile products are developing in the direction of high efficiency, low consumables, and low energy consumption. For example, through atomic substitution and compound doping, the rare earth-free ZK-5B high-performance motor magnetic tile independently developed by the company reduces the coagulation of magnetic powder, improves the orientation effect, improves the material performance and reduces the production cost by using strong magnetic field to suppress and adding a double dispersant.